SOIL AND TISSUE TESTING TECHNOLOGY

Learn how our turnkey process is faster

and easier to operate than traditional

soil analysis methods.

Introducing the laser based technology for soil testing

What is LIBS?

Laser-induced breakdown spectroscopy (LIBS) is a powerful analytical technique that is used to analyze materials. It has numerous applications, from pharmaceuticals to mining, and is even used by NASA rovers to explore Martian soil.

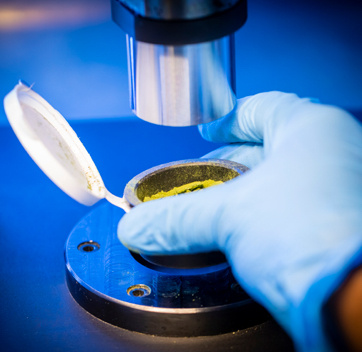

LIBS enables a direct, rapid, simultaneous, multi-element, low analytical cost, and environmentally clean analysis that requires little sample preparation.

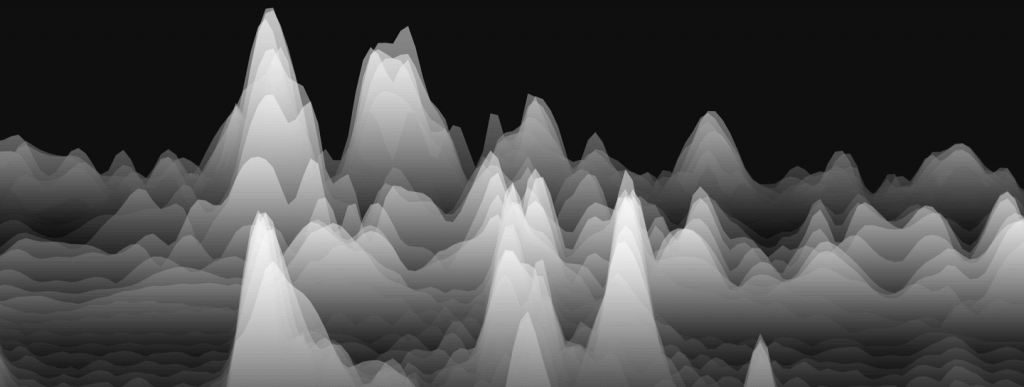

It works in three very rapid steps: first, a powerful laser is fired at the sample surface, irradiating it, and therefore creating a plasma. When the laser is turned off, the samples’ electrons return to their previous state, emitting the absorbed energy as electromagnetic radiation. The radiation emitted by each element has a specific wavelength, which is measured and used to determine the precise elemental composition of the material sample.

Although LIBS is a very powerful system to identify and quantify elements in soils, the quantitative analysis is not so trivial, mainly in complex samples such as soils, which present quite varied compositions both in terms of texture, granulometry, and chemical composition.

The LaserAg system is a very special application of the powerful LIBS technology. We have created and patented a process to enable it to analyze very complex matrices, such as agricultural soil, forage, and plant tissue, in addition to quantifying the identified elements.

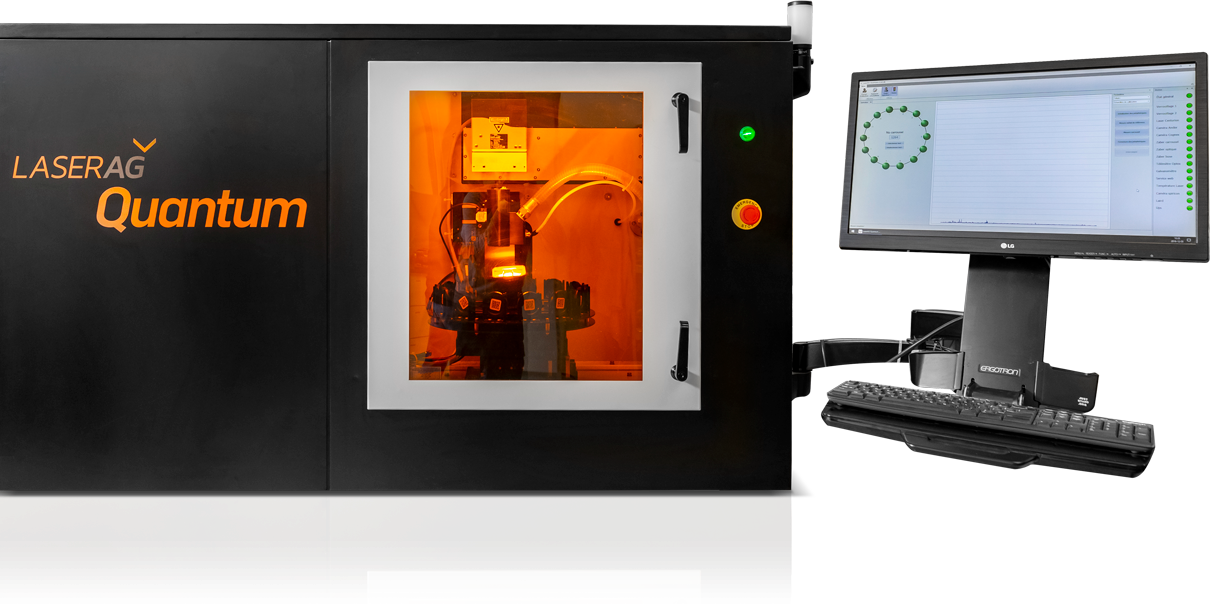

WHAT IS LASERAG QUANTUM?

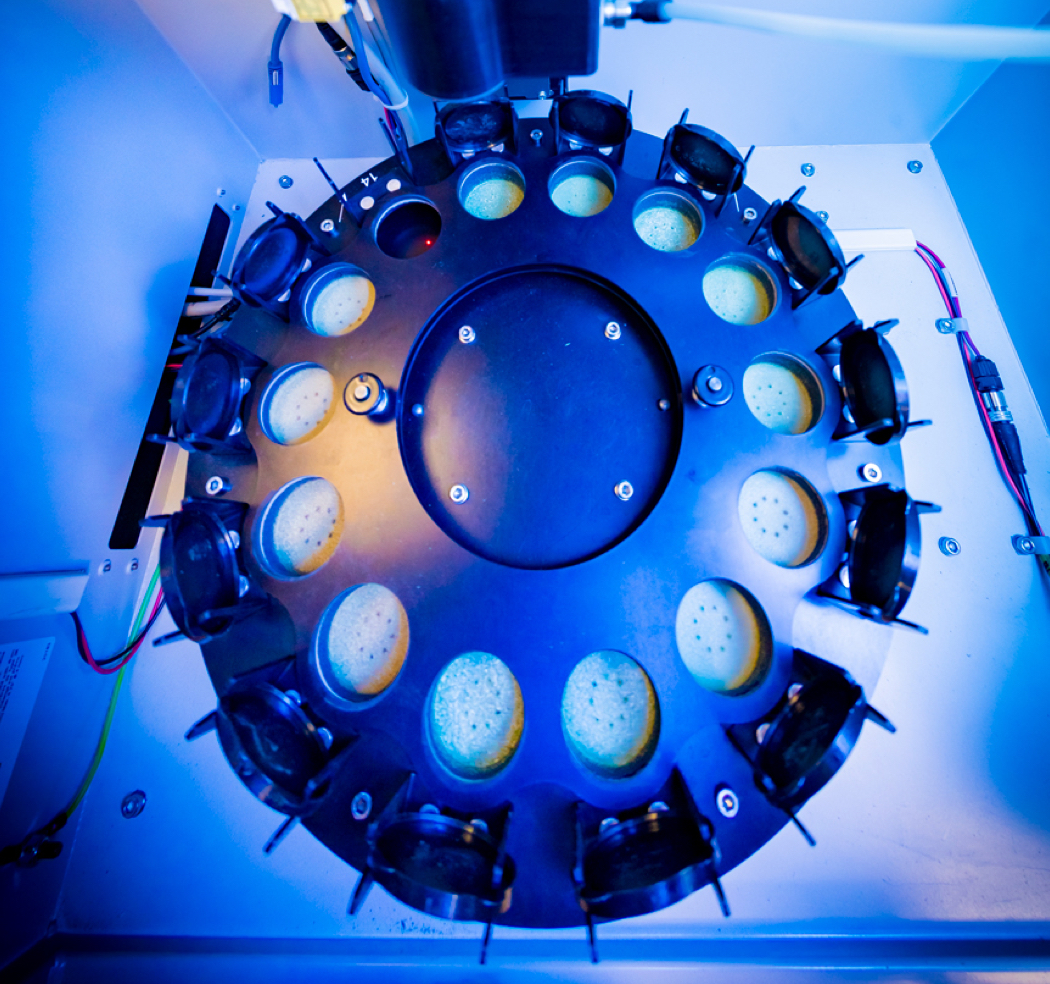

LaserAg™ Quantum is a laboratory equipment developed by Logiag that analyzes agro-environmental samples using a laser-induced plasma spectroscopy (LIBS) technology. In only a few minutes, this device provides a multitude of parameters, including:

Patents

The sampling and analysis processes of LaserAg are patented.

software

LaserAg has developed the following software to support its process:

LaserAg Partner, which allows you to view the sampling route to be carried out as well as the analysis results obtained with the LaserAg Quantum equipment.

LaserAg Sampler, a mobile app equipped with a GPS that guides your team in the fields on where to collect the samples. It also allows for the samples to be geopositioned. which allows the laboratory technician to view the results of the LaserAg Quantum (in real-time).

LaserAg Quantum, a software that allows the laboratory technician to control the machine.

LIMS, a laboratory management system used which allows the laboratory technician to view the results of the LaserAg Quantum (in real-time).