Collecting the samples

The LaserAg process starts in the field, where the samples are collected and placed in a container. A QR code on the container is then read using the LaserAg Sampler mobile app to identify and geolocate the samples.

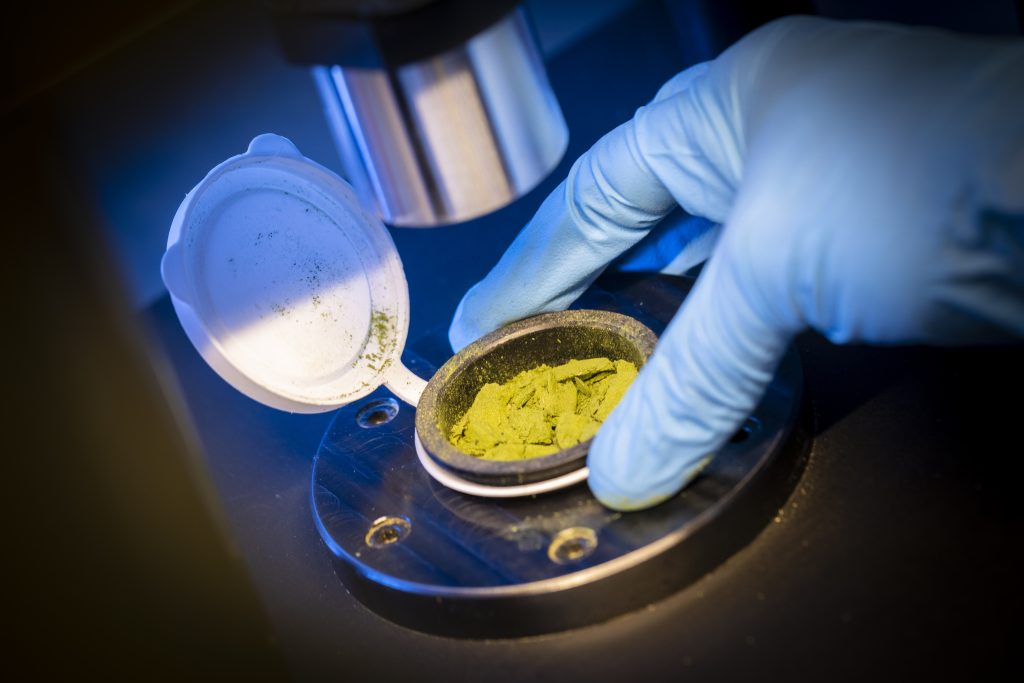

Preparing the samples

Once the samples arrive at a laboratory equipped with both a LaserAg Press and a LaserAg Quantum machine, the soil is dried. To ensure a near-null percentage of moisture in the sample, we recommend a 24-hour drying period at 37°C.

Once dried, samples are grinded, placed in a cup, and pressed using the LaserAg Press, to transform them into a stable rock-like surface.

Analyzing the samples

At this point, the samples are ready for analysis.

Up to 14 samples can be placed on a carousel which is installed on its rack in the LaserAg Quantum machine.

Analysis of the 14 samples takes only 20 minutes.

When the analysis is complete, the sample cups can be removed from the rack, stored, or emptied and recycled. The system produces no chemicals and no by-products, leaving behind only the recyclable cup and a small amount of soil, forage, or plant tissue.

Calibrating the equipment

Collect 2,000 samples representative of the territory you will ultimately serve. The samples should include the range of both soil types and nutrient concentrations that are likely to be found on the territory, from poor to excessively rich. For plants, the samples should be representative of the crops grown on the territory.

Split each sample in half after it has been homogenized. One half will be put in a cup for the LaserAg Quantum analysis, and one will be sent to a local laboratory to be measured using the traditional method.

The results of the local laboratory must be entered into the LaserAg Quantum calibration software LIMS.

Using 1,500 samples, Logiag will calibrate the machine, and the remaining 500 samples will be used to validate the calibrated model. You will then be provided with a report explaining the validation results, e.g., the precision and accuracy of the technology. The performance of LaserAg Technology is likely to improve as the number of calibration samples increases.